Chain Pump

Navindran S/O Chandran/ Navindran Chandran

Diploma in Mechnical Engineering @Singapore Polytechnic

Works as Fablab Assistant @ Fablab @Singapore Polytechinc

Diploma in Mechnical Engineering @Singapore Polytechnic

Works as Fablab Assistant @ Fablab @Singapore Polytechinc

This is my module project and I don't know what grade I get. The module called Engineering Invention from Engineering Academy. Basically this project is about Ancient Invention the theme I get is South- East Asia Ancient Invention. I had a group of consist of 3 DEEE( Dip.Electrical & Electronic Engineering) student and 2 DME(Dip.Mechanical Engineering) student. So we were told select 3 Asian Ancient Invention. So we select Water-clock , Chain pump and Water - Hammer. Then my lecturer in- charge ask us to do Chain pump..

So what I had in my mind was last time I did a project where I have a rusty attachment chain that I buy to make a threaded wheel. So I use that. So we had 2 prototype presentation

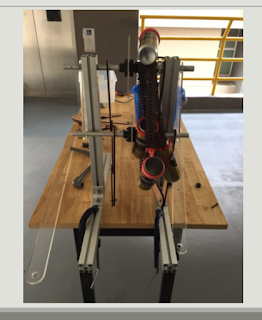

So this will be the first one;

From the left; The overall prototype, electronic component , and the support system..

So what I had in my mind was last time I did a project where I have a rusty attachment chain that I buy to make a threaded wheel. So I use that. So we had 2 prototype presentation

So this will be the first one;

From the left; The overall prototype, electronic component , and the support system..

Challenges:

Problem that we face was the attachment chain and the sprocket doesn't fit as we were using Bicycle sprocket and K-35 attachment chains.

Our prototype was a kind of big and take to much space

No Mobility. Cannot move around with that.

Improvement that targeted to do:

Use only one stand and make it retractable

Decrease the chain size by half

Find a suitable Sprocket.

Do a stopper that we can only rotate it in one direction.

Second and Final Prototype:

The Second prototype was a success but there was no good finishing as the rusting of the chain becoming worse but the prototype works.

What I did??

I use a 8mm acrylic as a working support where we attached the acrylic to connect the driven and effort shaft together firmly and it's works.

Not only that I found the file for K-35 sprocket online:

I just laser cut using acrylic .

I tried to 2d router using aluminium but it doesn't turn out well. So we stick with acrylic.

Breaking the chain is the hardest thing that I do in this project .

But I manage too break it.

Below will be the CAD drawing report that maybe will give you the understanding.

For more brief pictures I will send put the pdf file.

Materials that I use for this project:

- Aluminium Extrusion 40 x 40 L500mm&L400mm(Support system)

- Acrylic 3mm 8mm( For sprocket, hooks, one way gear mechanism, box for electronic parts and the working support)

- Steel pipe D6mm L200mm

- PVC pipe D10mm L500mm ( we use it for the lever with 90degree connector)

- M4 screw multiple lengths

- Wood for the retractable usages

- K35 attachment chain.

- Tin cans

- ABS for 3d printing purpose

- LCD screen

- Ultrasound sensor 2

- Bluetooth receiver..

- Adjusting switch

- Arduino kit

- Connecting Wire.

Fabrication Techniques

- 3D- printing

- Laser cutter

- 2D- router

- Vertical Miling

Target that I achieve:

Make it portable (ACHIEVED)

Make it smaller then first project(ACHIEVED)

Make a stopper ( ACHIEVED)

Find a suitable sprocket(ACHIEVED

Video:

No comments:

Post a Comment