Navindran S/O Chandran/ Navindran Chandran

Diploma in Mechnical Engineering @Singapore Polytechnic

Works as Fablab Assistant @ Fablab @Singapore Polytechinc

Hi guys,as I said in the last post yesterday, I try out the experiment and I have a good results

Shout out to Tze Chuan for the comment it was really helpful.

Now I will be discussing about my cubicon setting:

This is the setting I put for the mounting that I did.

This will be the time taken to print and details about the layers and tolerance

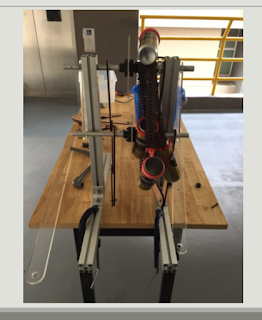

The execution of the experiment

I did this in one try and it works gladly

The picture below will be the time I slot in the M8 nut

The slotting in the M8 nut need some gut feeling and some calculation as one layer is 0.2mm you will roughly know when to slot the nut in . Please make sure that you guys take in the consideration of the nozzle head as the nut may effect the printing . Believe it or not I was sitting infront of my 3D printer for 45 minutes from the time my hexagon start forming just to get the confidence to slot in my M8 nut .Phew... Any way it's done and I'm happy to see the final product.

The Final product:

Sorry if you guys can't see the M8 nut as my lab here have poor lighting and my smartphone camera is not that good.

This is the video with mmy lead screw to see whether it's working or not

It works fine for now let see when I add my other parts.

As ABS have a mechanical properties :

I think this experiment that I have succeed will work for a long time

Thanks,

Regards,

Navin